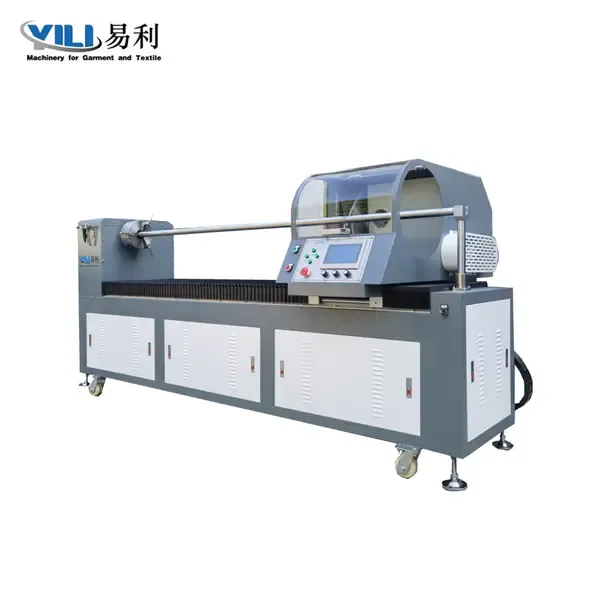

1.The same material can be cut into 9 sets of size, multi-level cutting, different widths and different amounts of cutting can be set freely, the cutting accuracy is high;2.Use microcomputer PLC, man-machine interface touch screen, computer program control data input;

3.The cutter spindle adopts electronic frequency conversion speed regulation;

4.Equipped with a safety alarm, if the spindle chuck is not completely put away, the machine will alarm to ensure safe operation;

5. Equipped with a safety cover that surround the cutter;

6.Equipped with professional dust collector device, it is more convenient to clean;

7.With automatic knife sharpen function during cutting;

8. Use high-quality brand electrical components to ensure stable and durable operation of the machine; use servo drives for more precise cutting;

9. Optional: cold air device, oil spray atomization device.

Specification:

1.Max working width: 2100mm

2.Max fabric diameter: φ350mm

3.Min slitting width: 4mm

4.Total power: 4.5KW

5.Voltage: AC 1Phase 220V/ 50HZ

6.Machine dimension(L*W*H): 2820x1210x1340mm

7.Available knife size: φ250Xφ38X2.8—φ350Xφ38X3.0

8.Need connect with air compressor: 0.4-0.8Mpa