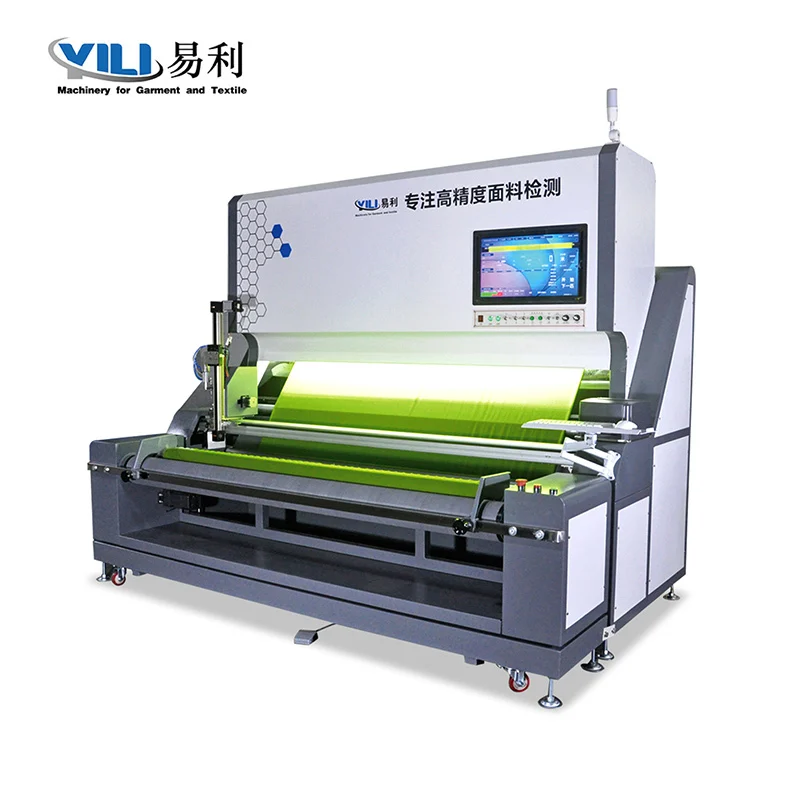

Artificial Intelligence Automatic Fabric Inspection Machine Model:YL-2021AI (Roll to Roll)

Model: YL-2021AI

Voltage: AC 1PH 220V 50HZ

Rated Power: 4.5Kw

Defect inspection rate: ~75% (Visible defect to the naked eye)

Inspection rate: Max. 40m/min (not include labeling time)

Detection precision: Max.5mm

Product feature

● Detectable defect type

Snag, hole, flying catkins, warp breaks, creases, weft breaks, long warp and weft defects, stain, pinholes, color fiber, knot

Applicable fabric types

Solid color normal knit and denim fabric.

Product advantages

Specification

| Model | YL-2021AI | Fabric working width | 2100mm |

| Voltage | AC 1PH 220V 50HZ | Labeling position | ±6cm |

| Rated Power | 4.5Kw | Fabric working diameter | 40cm |

| Defect inspection rate | ~75%(Visible defect to the naked eye) | Length measurement deviation | ≤0.5% |

| Inspection rate | Max. 40m/min(not include labeling time) | Width detect deviation | ±2cm |

| Detection precision | Max.5mm |

Product Details

Do you have any questions? Welcome to leave us a message

![]() We have over 30 years of rich production experience in the manufacturing process of pre-sewing and post-sewing equipment.

We have over 30 years of rich production experience in the manufacturing process of pre-sewing and post-sewing equipment.

![]() Obtained over 50 patents, possesses a comprehensive reserve of automation technology, and continues to invest in research.

Obtained over 50 patents, possesses a comprehensive reserve of automation technology, and continues to invest in research.

![]() We have established customer project cooperation in more than 80 countries around the world.

We have established customer project cooperation in more than 80 countries around the world.

![]() Global Cooperation with Quality & Innovation. Pre-and Post-Sewing Equipment Solutions Provider.

Global Cooperation with Quality & Innovation. Pre-and Post-Sewing Equipment Solutions Provider.

Contacts: Jessica Mo

Tel: +86-0758-8512058

Tel: +86-13827530181

WhatsApp: +86-13827530181

E-mail: jessicamo@ylzq-tech.com

Add.: Jindu Industrial Park, Gao Yao District, Zhaoqing City,Guangdong, China.